When it comes to drilling concrete you’re faced with two legitimate tools to choose from, a rotary hammer drill or a hammer drill.

Both produce a hammering motion as the bit turns, however, the way they create this motion is slightly different due to variations in design.

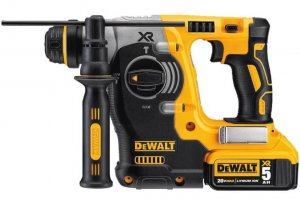

Rotary hammers use a piston mechanism that utilizes air pressure to power the drill bit forward and backward. This mechanism allows rotary drills to produce much more impact energy than hammer drills.

While the chucks in hammer drills move in the same manner, the mechanism by which it achieves this is different.

Instead of a piston mechanism, it uses a special clutch system with two ridged gears. As they spin, the ridges cause them to ride up and down, creating a back and forth motion.

What is a rotary hammer used for?

The piston mechanism makes rotary hammer drills ideal for much larger and tougher jobs such as drilling and chiseling into:

- masonry walls

- stone

- brick

- mortar

- hard concrete

They also feature a hammer only mode with no bit rotation for light demolition and construction work.

What is a hammer drill used for?

Hammer drills are perfect for light masonry work. They are also extremely popular with woodworkers with the drill only mode allowing you to go from drilling concrete to putting holes through wood in the blink of an eye.

Can a rotary hammer be used as a jackhammer?

Rotary hammers have a hammer only mode that can be used alongside a chisel, flat or point bit for breaking up material. So technically yes, they can be used as an electric jackhammer, all be it a mini one.

Can a hammer drill be used as a regular drill?

The clutch system used by hammer drills allows them to be used as a regular drill by turning off the hammering action.

While in drill only mode they can be used for metal and wood-related projects.

The only drawbacks to using a hammer drill as a regular drill is the cost and bulkier design.

Pros & Cons

Pros of A Rotary Hammer

Powerful

Rotary hammer drills are by far the more powerful of the two. If you need to remove tiles from your bathroom wall or punch holes greater than 1’’ in diameter into hard concrete, a rotary hammer should be your tool of choice. As far as speed goes, they actually generate fewer impacts per minute than a hammer drill, however, each blow is more powerful.

Work Capacity & Versatility

Rotary hammers are made for heavy-duty drilling work on the toughest materials. They can produce holes up to 2’’ in diameter, double the capacity of a standard hammer drill. They are particularly versatile as well, with many accessories available including chisel, bushing and point attachments.

Corded

When it comes to corded vs cordless, corded rotary hammers are probably still your best bet. They deliver more reliable power over the entire duration of a job, with no drops in power.

Mini Jackhammer

Hammer only mode removes bit rotation, turning your rotary hammer drill into a mini jackhammer that can be used for light demolition work. While it won’t quite reach the power levels of an actual jackhammer, it will be much lighter and still a great option for construction workers.

Cons of A Rotary Hammer

Weight & Ease of Use

Rotary hammers are heavier and bigger than a hammer drill and while the added mass dampens vibrations felt by the user and improves durability, it can make them harder to use. For the casual user, a rotary hammer is overkill, a hammer drill is far more suitable.

Cordless

Cordless rotary hammers are always improving, with many capable of higher peak power than a corded rotary hammer drill. However, using them on longer projects increases the likelihood of burning out the battery. Replacing it every couple of years can get costly.

Specialty Bits

Due to their superior power output, rotary hammers require special bits that lock into place twice. Once by screwing the bit into the chuck and then by screwing a left-threaded screw through the chuck into the bit. Recent models feature tool-free SDS-plus chucks, however, they are more expensive.

Although this method creates a solid connection, it limits the bits you can use with a rotary drill. Some manufacturers even create unique chucks, meaning the user is confined to using bits only made by that company.

Price

Rotary hammer drills are the more expensive option of the two, with budget options available around the $100 mark and top-end models going for $300-400.

Pros Of A Hammer Drill

Useability

Hammer drills are much lighter, in fact, you’ll be hard-pressed to find one heavier than 8lbs! Being only slightly larger than a normal drill they are very user-friendly, great for light to medium tasks around the house. A small form factor and removable ergonomic adjustable handle make them easy to use in a range of situations.

Drill Only Mode

The clutch system allows many hammer drills to be used as regular drills by simply switching the hammering action off. This opens up the ability to work with metal and wood, something that isn’t possible with a rotary hammer.

Affordable

Price-wise hammer drills are much more affordable, with 6-8 amp motor drills going for $50-100 and 7-10 amp motor drills going for $100-150.

Cons Of A Hammer Drill

Less Power

While a hammer drill produces more impacts per minute, each blow is less powerful than those produced by rotary hammers. More beats per minute also result in greater vibration. Add in the smaller form factor and the user experience can become uncomfortable. Leading manufacturers are starting to implement vibration dampening technologies, however.

Limited Capacity

A hammer drill is not designed to drill large holes (1’’ diameter capacity) or work with tough material. Attempting this is a good way to burn out even the most powerful hammer drills.

Conclusion

So, rotary hammer vs hammer drill, which drill hammer is for you?

The answer comes down to your intended application. Let’s explore various applications and which of the drills you would need to accomplish them.

The versatility of a rotary hammer makes it useful for a multitude of jobs. Of course, where it shines the most is when it’s used for heavy-duty tasks on larger projects. Various speed settings and drill attachments make anything from tile removal to drilling holes into concrete and breaking it up a walk in the park. A good rotary hammer is a must-have for any serious trade professional.

On the other hand, hammer drills are much better suited for handymen performing DIY projects around the house. They can drill holes up to ½’’ in a variety of materials, making a task like adjusting hinges and other small scale tasks a breeze. While they excel when used for brick and masonry work, they can be used on concrete, it’ll just take slightly longer and put unnecessary strain on the motor.

Reader Interactions