An oscillating spindle sander is a type of woodworking tool that is used to smooth out rough surfaces on wood, metal, and other materials. The machine consists of a rotating spindle that moves up and down in a circular motion, while the sandpaper attached to it sands the surface. The oscillating motion of the spindle helps to prevent the buildup of heat and friction, which can cause damage to the material being sanded.

The spindle of an oscillating spindle sander is typically powered by an electric motor and is mounted on a table. The table can be adjusted to different angles to allow for sanding at different angles and positions. The sandpaper is attached to the spindle using a special adhesive or by using a hook and loop system that allows for quick and easy changes of sandpaper grits. The oscillating motion of the spindle helps to prevent the sandpaper from clogging with dust and debris, which can reduce the effectiveness of the sanding process.

Understanding Oscillating Spindle Sander

An oscillating spindle sander is a tool that is used to sand curved or contoured surfaces. It is especially useful for sanding small, difficult-to-reach areas. The sander consists of a spindle that is mounted on a motor, and a sanding sleeve that fits over the spindle. The spindle oscillates up and down while rotating, which helps to prevent the sandpaper from clogging and prolongs its life.

The oscillating motion of the spindle helps to distribute the wear on the sandpaper evenly, which means that the sandpaper lasts longer and the sander is more efficient. The sander can be used on a variety of materials, including wood, metal, and plastic.

When using an oscillating spindle sander, it is important to choose the right grit of sandpaper for the job. The grit refers to the coarseness of the sandpaper, with lower numbers indicating a coarser grit and higher numbers indicating a finer grit. Coarser grits are used for removing material quickly, while finer grits are used for finishing and smoothing.

The sander can be used for a variety of tasks, including sanding curves, shaping edges, and smoothing surfaces. It is especially useful for sanding small parts, such as spindles and dowels, that would be difficult to sand by hand.

Overall, the oscillating spindle sander is a versatile and efficient tool that is useful for a variety of sanding tasks. With the right sandpaper and technique, it can help to achieve a smooth and professional finish on a variety of materials.

Working Principle of an Oscillating Spindle Sander

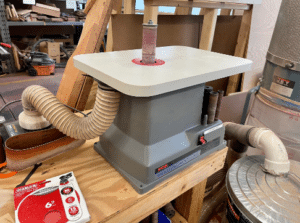

An oscillating spindle sander is a type of sanding machine that is used to smooth and shape wood, metal, and other materials. The machine consists of a table, a spindle, and a sanding sleeve. The spindle is mounted vertically on the table and is driven by a motor. The sanding sleeve is attached to the spindle and rotates as the spindle turns.

The working principle of an oscillating spindle sander is based on the combination of rotary and oscillating motion. The spindle rotates in a circular motion while at the same time oscillating up and down. This motion creates a unique sanding pattern that is more efficient and effective than traditional sanding methods.

The oscillating motion of the spindle ensures that the sanding sleeve does not become clogged with sawdust, which can reduce the efficiency of the machine. The sanding sleeve moves up and down, which allows it to sand in a more uniform manner. This motion also helps to prevent burn marks on the surface of the material being sanded.

The table of the oscillating spindle sander can be adjusted to different angles, which allows for greater versatility in sanding different shapes and sizes of materials. The sanding sleeve can also be easily changed, which allows for different grits of sandpaper to be used depending on the desired finish.

Overall, the working principle of an oscillating spindle sander is based on the combination of rotary and oscillating motion to create a unique sanding pattern that is efficient and effective. The machine is versatile and can be used to sand a variety of materials, making it a valuable tool for woodworkers, metalworkers, and other craftsmen.

Key Components of an Oscillating Spindle Sander

An oscillating spindle sander is a power tool used for sanding and shaping wood, metal, and other materials. It consists of several key components that work together to deliver precise and efficient sanding results. In this section, we will discuss the main components of an oscillating spindle sander and their functions.

The Motor

The motor is the heart of an oscillating spindle sander. It provides the power needed to rotate the spindle and oscillate it back and forth. The power of the motor determines the speed and efficiency of the sander. Most oscillating spindle sanders come with a motor that ranges from 1/2 to 3 horsepower. Higher horsepower motors are better suited for heavy-duty sanding tasks.

The Spindle

The spindle is the rotating part of the sander that holds the sanding sleeves. It is attached to the motor and rotates at high speed to sand the workpiece. The spindle can be adjusted to different angles and heights to accommodate different sanding needs. It also oscillates back and forth to ensure even sanding across the workpiece.

The Table

The table is the flat surface on which the workpiece is placed. It is usually made of cast iron or aluminum and can be tilted to different angles to accommodate different sanding needs. The table is also equipped with a miter gauge that helps in making angled cuts and precise sanding.

The Dust Collection System

The dust collection system is an important component of an oscillating spindle sander. It helps to keep the work area clean and free of dust and debris. The system consists of a dust port that connects to a vacuum or dust collector. As the sander operates, the dust and debris are sucked into the dust port and collected in the vacuum or dust collector.

In summary, an oscillating spindle sander is a versatile and efficient power tool that consists of several key components, including the motor, spindle, table, and dust collection system. Each component plays a critical role in delivering precise and efficient sanding results.

Process of Using an Oscillating Spindle Sander

Setting Up the Machine

Before using an oscillating spindle sander, it is important to ensure that it is set up properly. Here are the steps to follow:

- First, make sure the machine is turned off and unplugged from the power source.

- Next, attach the spindle to the machine by inserting it into the spindle housing and tightening the lock nut.

- Adjust the height of the table to the desired level by turning the height adjustment knob.

- Install the appropriate sanding sleeve onto the spindle. The sanding sleeve should fit snugly onto the spindle and not wobble.

- Finally, plug in the machine and turn it on to ensure that it is working properly.

Sanding Process

Once the machine is set up, it is ready to be used for sanding. Here are the steps to follow:

- Choose the appropriate grit sandpaper for the material being sanded. Lower grits are used for rougher materials, while higher grits are used for smoother materials.

- Turn on the machine and wait for it to reach full speed before beginning to sand.

- Hold the material being sanded firmly against the table and move it back and forth along the spindle. It is important to keep the material moving to prevent burning or uneven sanding.

- If necessary, adjust the height of the table to ensure that the material is being sanded evenly.

- When finished, turn off the machine and unplug it from the power source.

- Remove the sanding sleeve from the spindle and replace it with a new one if necessary.

By following these steps, users can effectively and safely use an oscillating spindle sander for their sanding needs.

Safety Measures While Using an Oscillating Spindle Sander

When using an oscillating spindle sander, it is important to take proper safety measures to avoid any accidents or injuries. Here are some safety measures that should be followed while using an oscillating spindle sander:

- Always wear safety glasses or goggles to protect your eyes from flying debris.

- Wear a dust mask to avoid inhaling sawdust or other particles.

- Avoid wearing loose clothing or jewelry that could get caught in the machine.

- Make sure the machine is properly grounded to prevent electrical shock.

- Keep your hands away from the sanding drum while it is in motion.

- Use a push stick or other device to feed the material through the machine.

- Do not force the material through the machine; let the machine do the work.

- Keep the work area clean and free of clutter to avoid tripping hazards.

By following these safety measures, you can ensure that you are using the oscillating spindle sander safely and effectively.

Final Thoughts

In conclusion, an oscillating spindle sander is a versatile and efficient tool that can be used for a variety of sanding tasks. Its oscillating motion ensures that the sandpaper wears evenly, which results in a smoother finish. The spindle sander is also very effective at sanding curved surfaces, making it an ideal tool for woodworking projects.

When using an oscillating spindle sander, it is important to follow all safety guidelines and to use the correct sandpaper for the job. The user should also ensure that the sandpaper is securely attached to the spindle, as loose sandpaper can cause damage to the workpiece and the machine.

Overall, an oscillating spindle sander is a valuable addition to any workshop. It is a reliable and efficient tool that can save time and effort when sanding. Whether you are a hobbyist or a professional woodworker, an oscillating spindle sander is a tool that you will not regret investing in.

Reader Interactions