Spindle sanders are a versatile tool that can be used for a variety of woodworking tasks, from sanding curves to smoothing out rough edges. However, some woodworkers may wonder if they can repurpose their spindle sander into a polisher. The answer is yes, it is possible to turn a spindle sander into a polisher with the right attachments and techniques.

To begin the process of turning a spindle sander into a polisher, woodworkers will need to purchase a polishing attachment that is compatible with their specific model of spindle sander. These attachments typically consist of a soft, flexible pad that is designed to hold polishing pads or discs. Once the attachment is secured to the spindle sander, woodworkers can begin polishing their woodworking projects with ease.

While turning a spindle sander into a polisher may seem like a simple process, it is important to note that not all spindle sanders are created equal. Some models may not have the power or speed necessary to effectively polish wood, while others may require additional modifications to function properly as a polisher. As with any woodworking project, it is important to do thorough research and seek advice from experienced woodworkers before attempting to repurpose a spindle sander into a polisher.

Understanding Spindle Sanders

Spindle sanders are woodworking tools that use a spindle-shaped sanding drum to sand curved or contoured surfaces. They are commonly used to smooth out rough edges, sand curves, and shape contours. Spindle sanders are often used in conjunction with other sanding tools, such as belt sanders or disc sanders, to achieve a smooth, even finish on a piece of wood.

Spindle sanders come in a variety of sizes and shapes, with different spindle lengths and diameters to accommodate different sanding needs. Some spindle sanders are designed to be mounted on a workbench, while others are portable and can be moved around the workshop as needed.

Spindle sanders typically use sanding sleeves, which are cylindrical pieces of sandpaper that slide over the sanding drum. The sanding sleeves come in different grits, ranging from coarse to fine, to accommodate different sanding needs. The sanding sleeves are easy to replace, making it simple to switch between different grits as needed.

Spindle sanders are not designed to be used as polishers. While they can be used to sand down rough surfaces and remove imperfections, they are not designed to provide a smooth, polished finish. Attempting to use a spindle sander as a polisher could damage the sanding drum or the piece being worked on.

Overall, spindle sanders are a versatile and useful tool for any woodworking shop. While they are not designed to be used as polishers, they are an essential tool for sanding and shaping curved or contoured surfaces.

Understanding Polishers

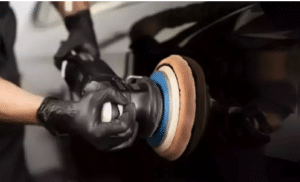

Polishers are power tools that are designed to remove scratches, swirls, and other imperfections from a surface. They are commonly used in the automotive industry to polish car bodies, but they can also be used on a variety of other surfaces, including wood, metal, and plastic.

There are two main types of polishers: rotary and dual-action. Rotary polishers are the most powerful and are used for heavy-duty polishing jobs. They spin in a circular motion and can generate a lot of heat, which can damage the surface being polished if not used correctly. Dual-action polishers, on the other hand, are less powerful and are designed for more delicate jobs. They oscillate in a circular motion and are less likely to cause damage.

Polishers come in a variety of sizes and shapes, and can be powered by electricity, battery, or compressed air. They typically use a polishing pad, which attaches to the tool and spins or oscillates to buff the surface being polished.

While a spindle sander is not designed to be used as a polisher, it may be possible to repurpose it for this use with some modifications. However, it is important to note that using a tool for a purpose other than what it was designed for can be dangerous and may void any warranties. It is recommended to consult with a professional before attempting to modify a tool.

The Conversion Process

Tools Needed

To convert a spindle sander into a polisher, the following tools are needed:

| Tool | Purpose |

|---|---|

| Buffing wheel | For polishing |

| Buffing compound | For polishing |

| Screwdriver | To remove the sanding drum |

| Wrench | To remove the sanding drum |

Safety Precautions

Before starting the conversion process, it is important to take the following safety precautions:

- Turn off and unplug the spindle sander.

- Wear gloves and safety glasses to protect hands and eyes.

- Work in a well-ventilated area to avoid inhaling dust.

Step-by-Step Guide

The following step-by-step guide outlines the process for converting a spindle sander into a polisher:

- Remove the sanding drum from the spindle sander using a screwdriver and wrench.

- Attach the buffing wheel to the spindle sander in place of the sanding drum.

- Apply buffing compound to the buffing wheel.

- Turn on the spindle sander and adjust the speed to the desired level.

- Hold the item to be polished against the buffing wheel, applying light pressure.

- Continue polishing until the desired level of shine is achieved.

It is important to note that not all spindle sanders are suitable for conversion into polishers. It is recommended to check with the manufacturer before attempting the conversion process.

Potential Challenges and Solutions

Converting a spindle sander into a polisher can be challenging, but it is not impossible. Here are some potential challenges that one may face and their possible solutions.

Challenge 1: Lack of Power

One of the primary challenges of converting a spindle sander into a polisher is the lack of power. Spindle sanders are designed to remove material, and they typically operate at a lower speed than polishers. This can result in a lack of power when trying to polish a surface.

Solution: One possible solution is to use a speed controller to increase the speed of the spindle sander. This can help to increase the power of the motor and make it more suitable for polishing. Another option is to use a different type of motor altogether, such as a high-speed motor.

Challenge 2: Different Accessories

Another challenge is that spindle sanders and polishers use different accessories. Spindle sanders typically use sanding sleeves or drums, while polishers use buffing pads or polishing discs.

Solution: One solution is to purchase a conversion kit that includes the necessary accessories for converting a spindle sander into a polisher. Alternatively, one can purchase the necessary accessories separately and modify them to fit the spindle sander.

Challenge 3: Dust Collection

Spindle sanders typically have a dust collection system to remove sawdust and debris from the work area. However, when using a spindle sander as a polisher, there is no need for a dust collection system. This can result in a messy work area.

Solution: One solution is to remove the dust collection system and cover the opening with a piece of tape or a cap. Another option is to modify the dust collection system to be used as a vacuum system for removing polishing debris.

In conclusion, converting a spindle sander into a polisher can be challenging, but with the right tools and modifications, it is possible. By addressing the challenges of power, accessories, and dust collection, one can successfully convert a spindle sander into a polisher.

Benefits of Conversion

Converting a spindle sander into a polisher can provide several benefits. First and foremost, it can save you money. Instead of buying a separate polisher, you can use the existing spindle sander and convert it into a polisher. This can be a cost-effective solution, especially if you have a limited budget.

Another benefit of conversion is that it can save you space. If you have limited workspace, you may not have enough room for both a spindle sander and a polisher. By converting the spindle sander into a polisher, you can save space and still have access to both tools.

Converting a spindle sander into a polisher can also be a time-saver. Instead of having to switch between two different tools, you can use the same tool for both sanding and polishing. This can save you time and increase your productivity.

Finally, converting a spindle sander into a polisher can be a fun DIY project. It can be a great way to learn about your tools and how they work. It can also be a satisfying accomplishment to create a new tool from an existing one.

Overall, converting a spindle sander into a polisher can be a cost-effective, space-saving, time-saving, and fun DIY project.

Limitations and Considerations

When considering turning a spindle sander into a polisher, there are several limitations and considerations to keep in mind.

Firstly, a spindle sander is not designed to be used as a polisher. While it may be possible to modify the machine to perform this function, it is important to understand that doing so may void any warranties or guarantees that came with the original device. Additionally, using a spindle sander in this way may cause damage to the machine or result in suboptimal polishing results.

Another consideration is that a spindle sander typically has a limited range of motion. This means that it may not be able to reach all areas of a workpiece, particularly if it has complex or irregular shapes. This can make it difficult to achieve a uniform finish across the entire surface of the object being polished.

Finally, it is important to consider the type of material being polished. Different materials may require different types of polishing tools or techniques, and a spindle sander may not be suitable for all materials. For example, polishing metal may require a different approach than polishing wood or plastic.

Overall, while it may be possible to turn a spindle sander into a polisher, it is important to carefully consider the limitations and potential drawbacks of doing so before attempting any modifications.

Conclusion

In conclusion, it is possible to turn a spindle sander into a polisher with the right attachments and accessories. However, it is important to note that a spindle sander is designed for sanding and may not have the power or speed required for polishing applications.

If you are considering converting your spindle sander into a polisher, it is recommended that you do your research and choose the right accessories for your specific needs. Some of the key factors to consider include the power of your spindle sander, the type of material you will be polishing, and the type of polishing pad or disc you will be using.

It is also important to note that converting your spindle sander into a polisher may void any warranties or guarantees that came with your original machine. It is recommended that you consult with the manufacturer or a professional before making any modifications to your spindle sander.

Overall, while it is possible to turn a spindle sander into a polisher, it may not be the most efficient or effective solution for all applications. It is important to weigh the pros and cons and choose the right tool for the job.

Reader Interactions