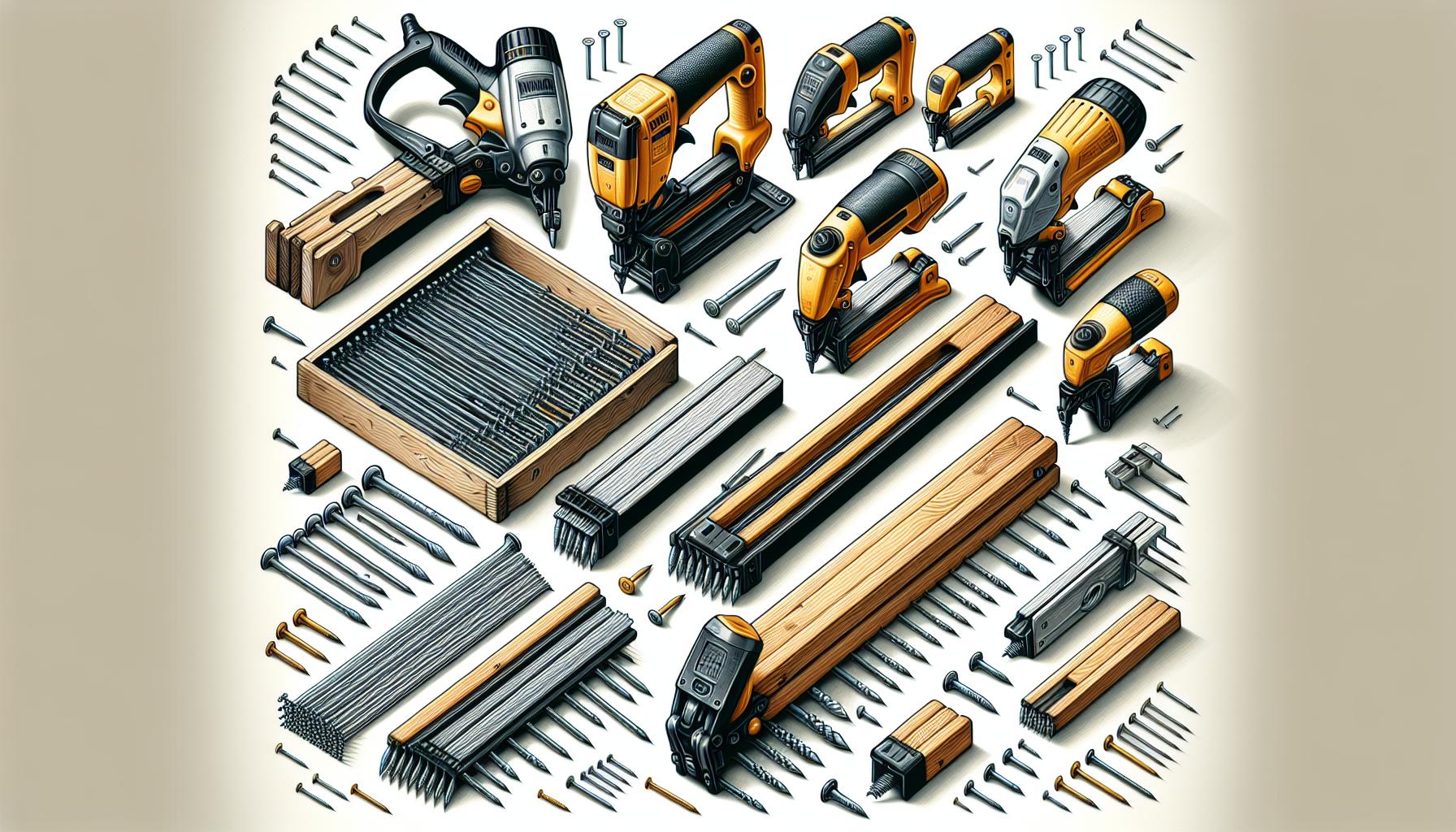

When tackling a woodworking project, choosing the right tool for the job is crucial. I’ve often found myself standing in the tool aisle, pondering the difference between a finish nailer and a nail gun. They might seem similar at a glance, but they serve distinct purposes.

A finish nailer is a type of nail gun, but it’s designed for more delicate work, providing a cleaner finish. On the other hand, a nail gun is a broader term that encompasses various types of nailers for different tasks. Understanding their differences is key to achieving professional results in your DIY projects.

What is a Finish Nailer?

In the world of carpentry and woodworking, a finish nailer is an essential tool that I often turn to for its precision and subtlety. It’s specifically designed to drive nails into trim work or other delicate pieces where a standard nail gun might be too powerful and cause damage. Finish nailers use thinner, smaller gauge nails, typically ranging from 15 to 16 gauge, which leave a small, almost imperceptible hole.

Finish nailers are perfect for tasks where aesthetics are crucial. They’re the go-to tool for installing baseboards, chair rails, door and window casings, cabinetry, and crown moldings. Due to their smaller head, the nails used in finish nailers can be easily putted over and painted, resulting in a flawless finish that’s highly desirable for interior work.

One of the key features of a finish nailer is its angled magazine. This design allows me to reach tight corners and spaces that would otherwise be inaccessible with a straight magazine tool. Moreover, many models are equipped with adjustable depth settings, enabling the fine-tuning of nail depth depending on the material’s hardness.

Here are the primary benefits of using a finish nailer:

- They provide a clean finish with minimal surface damage.

- The angled magazine allows for access in tight spots.

- There’s an adjustable depth of drive for precision.

- The thin gauge nails can be easily concealed for a polished look.

While finish nailers are typically pneumatic, relying on an air compressor to function, there are also cordless models available that offer greater mobility. The cordless versions run on batteries or fuel cells and are incredibly convenient for jobs where dragging a hose around would be cumbersome. Investing in a finish nailer is a smart move for anyone keen on achieving professional-grade results without the need for extensive wood filler or sanding.

What is a Nail Gun?

When I’m tackling a broad array of construction tasks, a nail gun is my go-to tool. It’s a type of power tool that rapidly drives nails into various materials, saving me time and energy. Unlike the more precise finish nailer, nail guns are versatile tools designed to handle heavier duty work, such as framing, roofing, and siding. There are several types of nail guns, each specialized for different jobs. They typically use larger gauge nails compared to finish nailers and can fire nails at a much quicker rate.

The most common nail gun variants include framing nailers, brad nailers, roofing nailers, and flooring nailers. Here’s why each is essential:

- Framing nailers are robust, designed for structural work and can handle long, large-diameter nails necessary for projects like building decks or houses.

- Brad nailers use smaller nails and are better suited for lightweight trim work, offering more precision than larger models.

- Roofing nailers are optimized for attaching shingles and have features like coil magazines to hold large quantities of nails.

- Flooring nailers are specialized tools used to install hardwood floor planks, ensuring seamless and secure fitting.

Nail guns operate using various power sources, such as pneumatics (compressed air), electricity, and even combustion. Pneumatic models are widely favored for their consistent power output and durability, although cordless electric variants are gaining popularity due to their portability.

With their impressive power and range of types, nail guns are indispensable for professionals and serious DIY enthusiasts alike. They are the workhorses of power tools, drastically reducing effort and time compared to manual hammering. Whether it’s framing out new construction or putting the final touches on a siding job, there’s a nail gun that’s perfect for the task.

The Differences in Design and Function

When I’m comparing finish nailers with nail guns, the nuances in their design and function really stand out. Finish nailers are crafted for precision work, featuring smaller, lighter bodies that allow me to easily maneuver the tool in tight spaces. They’re designed to fire thinner gauge nails, which are less likely to split the wood, making them ideal for trim work where I need a clean and discreet finish.

In contrast, nail guns are built for the demands of high-powered construction projects. The various types of nail guns have their own distinctive designs conducive to their job requirements. For instance, a framing nailer has a larger, more robust body that can handle driving substantial nails into framing lumber. This tool is not concerned with subtlety but with the brute strength required for structural work.

Here’s a quick rundown of different nail gun designs tailored to specific tasks:

- Brad Nailers: Designed for smaller trim work or delicate woodworking, using thinner, 18-gauge nails.

- Roofing Nailers: Built specifically for roofing materials, utilizing coil-style magazines to hold high volumes of nails.

- Flooring Nailers: They have a unique design that allows me to comfortably nail down flooring from a standing position, optimizing my leverage and efficiency.

The key differences in function between these tools are also evident in the size of nails they use and their magazine capacity. Finish nailers typically use 15 to 16-gauge nails and come with a straight magazine. On the other hand, the heavier-duty nail guns can handle nails ranging widely in size, often using angled magazines which afford a greater capacity and accessibility when working in cramped spots.

Understanding the power source is another significant factor in distinguishing between these tools. While some pneumatic nailers require an air compressor to generate the necessary power, others, like many cordless models, rely on internal combustion or battery power. This variance directly affects the tool’s portability and the consistency of the driving force during prolonged use.

| Nailer Type | Gauge Size | Nail Length Capacity | Power Source |

|---|---|---|---|

| Finish Nailer | 15-16 | 1″ – 2.5″ | Pneumatic/Cordless |

| Framing Nailer | .113-.131 | 1. |

When to Use a Finish Nailer

Knowing when to reach for my finish nailer as opposed to a general nail gun can make a significant difference in the quality and integrity of my projects. A finish nailer is most appropriate when I’m working on tasks that require a high degree of accuracy with less visible nail heads.

Here are common scenarios where a finish nailer overshadows a more robust nail gun:

- Installing Trim and Molding: Due to its precision, a finish nailer is my go-to tool for affixing baseboards, chair rails, and crown molding where a clean, discreet finish is paramount.

- Cabinetry and Woodworking Projects: In cabinetry, the last thing I want is to mar the surface with large nail entries. A finish nailer uses finer nails that are perfect for delicate work and leave a minimal footprint.

- Stair and Flooring Applications: When securing the last board or delicate pieces during flooring and stair installation, the smaller gauge nail used by finish nailers is ideal to prevent splitting or damaging materials.

Finish nailers are also distinguished by their ability to drive nails through hardwoods and engineered products with a finesse that doesn’t compromise the wood’s aesthetic or structural integrity. I always make sure the tool has the appropriate gauge and length of nail required for the job at hand. Remember that the type of finish work often dictates whether I’d use a 15 or 16-gauge nail with the corresponding finish nailer.

The finish nailer’s magazine capacity is designed to hold enough nails for me to work efficiently without constant reloading. However, if I’m tackling larger projects with extensive nailing requirements, I’ll often find a stick-style magazine more beneficial as it typically holds more nails compared to a coil-style.

Power source options for finish nailers include pneumatic, combustion, or battery-powered models. My choice depends on the mobility I need for the project and whether consistent power delivery is a concern. For indoor fine finish work, I gravitate towards electric or battery-operated finish nailers for their ease of maneuverability and clean operation.

When to Use a Nail Gun

When I’m tackling heavy-duty projects like framing, roofing, or siding, a nail gun becomes my go-to power tool. Unlike finish nailers, nail guns are engineered for quick and forceful applications. Their robust design allows them to handle larger gauge nails, which are essential for ensuring structural integrity in building projects.

One of the primary scenarios where I’d use a nail gun is during framing. Framing nailers are designed to join large pieces of wood or other framing materials quickly and securely. They can typically accommodate nails up to 3.5 inches, perfect for constructing the skeleton of a house or an outdoor deck. The nails driven by a framing nailer must be strong enough to hold substantial weight, which is why the nail gun’s power is crucial here.

Another situation that calls for a nail gun is when doing roofing tasks. Roofing nailers are specific to this field and are built to dispense nails fast enough to keep up with the demanding pace of laying shingles or roofing tiles. They also feature a wider head that helps prevent weather damage and dislodgment of the roofing material.

Installing siding is another area where nail guns shine. Siding nailers are special because they are designed to handle the specific type of nails that siding requires – nails that are long enough to penetrate sheathing and create a secure attachment, yet have a small enough head to be discreet and not impede the finished appearance.

When working on projects that require rapid nailing but not necessarily the finesse of a finish nailer, a nail gun is ideal. They save time and provide the driving power needed for materials that are tougher or thicker than those typically worked with using finish nailers. For any construction-centric project where time efficiency and nail size are significant factors, a nail gun is my undeniable choice.

In choosing the right nail gun, the type of project I’m working on always dictates the specific model and nail size I opt for. The variety of nail guns on the market cater to different needs, whether it’s for woodworking, metal-connecting, or concrete nailing, each designed to deliver the best results for their intended use.

Conclusion

Choosing between a finish nailer and a nail gun boils down to the project’s specifics and the precision required. I’ve outlined the nuances that set these tools apart, from the gauge of nails they use to their magazine capacities and power sources. Remember, for delicate trim and fine woodworking, a finish nailer is your go-to for a flawless finish. On the other hand, when tackling larger-scale construction tasks that demand speed and power, a nail gun will serve you best. Always match the tool to the task for efficiency and the best results. Armed with this knowledge, you’re now equipped to make the right choice for your next project.

Frequently Asked Questions

What is a finish nailer used for?

A finish nailer is used for precision work, ideal for tasks like installing trim and molding, cabinetry, woodworking projects, as well as stair and flooring applications. It’s designed to drive nails through hardwoods and engineered products without damaging the aesthetic or structural integrity.

How does a nail gun differ from a finish nailer?

Nail guns are built for high-powered construction projects and can handle a more comprehensive range of nail sizes compared to finish nailers. They are tailored for heavy-duty tasks such as framing, roofing, or siding and offer rapid driving power and efficiency.

What types of nails can a finish nailer use?

Finish nailers typically use 15 to 16-gauge nails and are selected based on the specific precision task at hand. It’s essential to choose the appropriate gauge and length of nail for the job to ensure optimal results.

When should you use a nail gun?

You should use a nail gun for heavy-duty construction projects that require quick and powerful nailing, such as framing houses, installing roofing materials, or applying siding. Nail guns are specialized to save time and increase efficiency in large-scale projects.

What are the benefits of stick-style magazines in finish nailers?

Stick-style magazines in finish nailers are beneficial for larger projects as they provide higher magazine capacity, allowing for more nails to be loaded at once. This reduces the time spent reloading and increases productivity.

What power source options are available for finish nailers?

Finish nailers come with various power source options, including pneumatic (air compressor-driven), combustion (gas cartridge-driven), and battery-powered models. The choice depends on the project requirements, mobility needs, and personal preference.

How do you choose the right nail size for a nail gun?

The right nail size for a nail gun is dictated by the specific project you are working on. Factors include the thickness and hardness of the materials being nailed together, as well as the type of nail gun being used (e.g., framing, roofing, or siding nailers).

Reader Interactions