When tackling a woodworking project, choosing the right tool can make all the difference. I’ve often found myself debating between a pin nailer and a finish nailer, each boasting its unique strengths. If you’re in the same boat, you’re not alone.

Pin nailers are the go-to for delicate trim work where hiding the nail is key, while finish nailers offer a bit more holding power for larger, more demanding jobs. Knowing which nailer to reach for can save you time and ensure a cleaner, more professional result.

I’m here to break down the differences, so you can nail your project with precision. Let’s dive into the world of pin nailers and finish nailers and find out which one’s the best fit for your next DIY adventure.

What is a Pin Nailer?

When tackling delicate woodworking tasks, I reach for my pin nailer, a precision tool designed for finesse. A pin nailer drives slender, headless pins into trim or molding. Because of their size—usually 23-gauge—the pins leave a nearly invisible hole after nailing. This is critical in projects where a clean, unblemished finish is the goal.

The pin nailer’s most significant advantage is that it doesn’t require wood putty to conceal the nail hole, saving me time and effort during the finishing phase of my projects. These tools are typically pneumatic, meaning they’re powered by an air compressor, though there are electric models available which are more portable but might lack the power of their pneumatic counterparts.

Ideal tasks for a pin nailer include:

- Attaching delicate trims and moldings

- Joining lightweight pieces where a larger nail could split the wood

- Work on detailed or fine-grade cabinetry

Pin nailers are not suitable for structural applications as the pins lack the sheer strength that screws or larger nails offer. But for adding a subtle touch or the final decorative elements to a project, it’s my go-to tool. It’s particularly useful in situations where the aesthetic is paramount, and the actual holding strength is of lesser importance.

Here’s a quick glance at the key features of pin nailers:

- Gauge: 23

- Nail Lengths: Ranges from 3/8 inch to 1-3/8 inches

- Capacity: Generally holds 100-200 pins per load

- Power Source: Pneumatic or electric

Understanding the limitations of a pin nailer is just as important as recognizing its strengths. It’s not the right tool for every job, but in the realm of fine woodworking and detailed finish work, it often plays an indispensable role.

What is a Finish Nailer?

When tackling larger woodworking projects, you’ll often need a tool that’s one step up from pin nailers. That’s where finish nailers come into play. These powerful tools are engineered to handle bigger jobs that require more holding power than what delicate pin nails can offer. Finish nailers use thicker and larger nails, usually ranging from 15 to 16-gauge, making them the ideal choice for attaching heavier trim pieces or for any task that demands a bit more strength.

Unlike pin nailers, the nails used in finish nailers do come with a small head, which means they will leave a more noticeable mark on the wood. This is why I make sure to follow up with wood putty to hide these imperfections when striving for a flawless finish. The nails capable of driving through hardwoods and provide ample support for door casings, staircases, and baseboards.

The features of finish nailers are similar to those of pin nailers, yet distinctively tailored for their particular tasks:

- They usually accommodate longer nails, often up to 2-1/2 inches.

- They offer various power sources like pneumatic, electric, and even battery-operated models.

- Some models feature angled magazines that allow you to reach tight spots with ease.

Despite their robustness, finish nailers are still quite precise, allowing you to work accurately without causing excessive damage to the wood’s surface. This precision is vital when I’m aiming for high-quality results in my cabinetry or trim work.

Considerations for Selecting a Finish Nailer:

- Determine the nail length you’ll commonly use, as this will influence the model you choose.

- Think about the environments you’ll work in—will you have access to a power supply, or do you need a cordless option?

- Assess the type of wood and materials you’ll be working with, which can vary from pine trim to oak baseboards.

Understanding the characteristics and capabilities of finish nailers is crucial for selecting the right tool for the job, especially when it’s important to strike a balance between holding power and the precision of the finish.

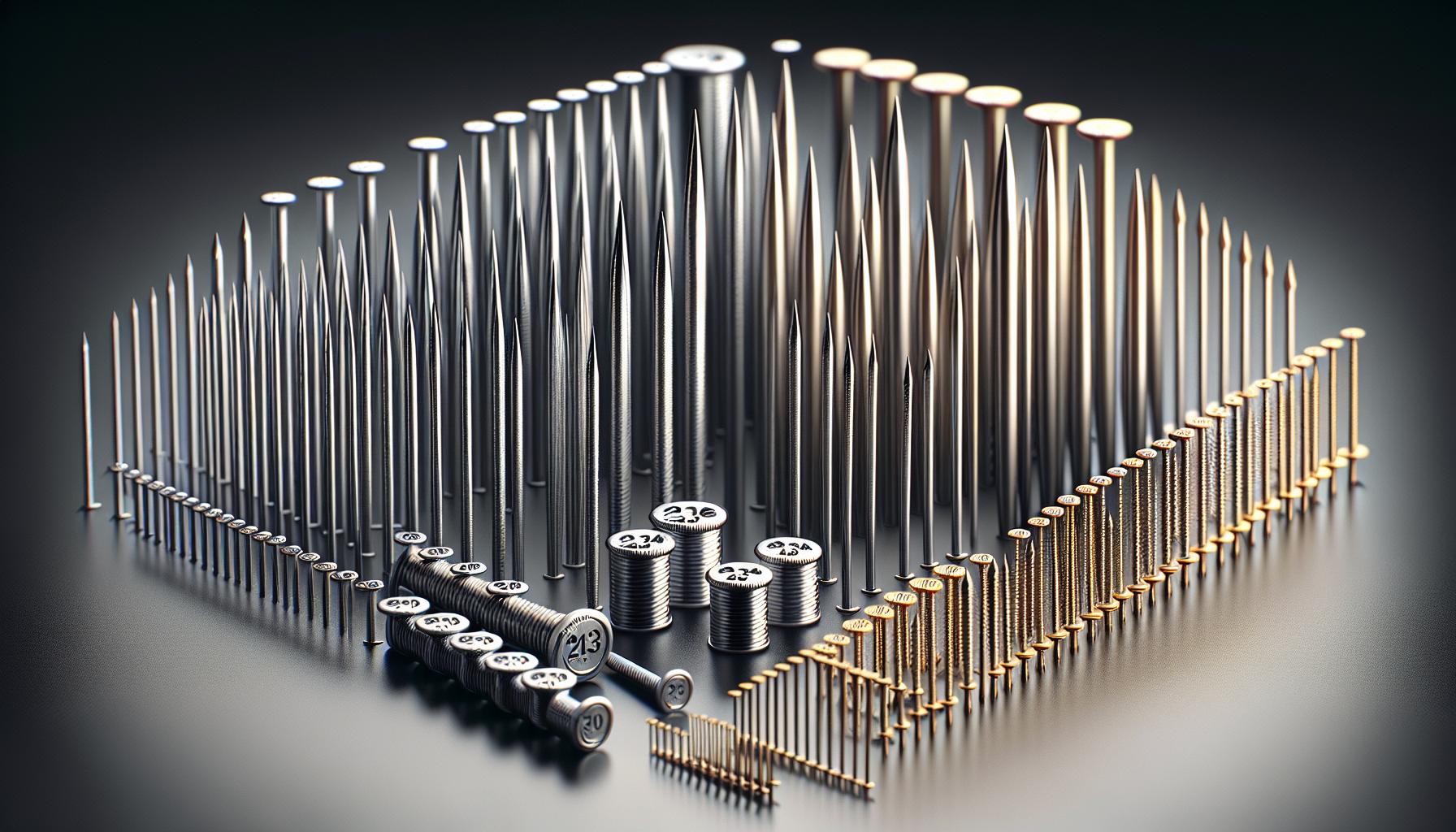

Differences in Nail Size and Type

When choosing between pin nailers and finish nailers, it’s critical to understand the variety of nail sizes and types they use. Pin nailers typically employ 23-gauge nails, the thinnest available, ranging in length from 3/8 inch to 2 inches. These pin-sized nails are almost invisible to the naked eye once inserted and leave a minuscule hole that rarely requires filling.

On the other hand, finish nailers are designed to handle larger nails, usually 15 to 16-gauge. The nails used in finish nailers can vary in length from 1 inch to 2-1/2 inches. The heads of these nails are more pronounced, making them noticeably more detectable on the surface. These differences are substantial as they directly impact the finishing quality and the holding strength of the fixed pieces.

To give you a clearer picture, I’ll break down the nail dimensions:

| Nailer Type | Gauge | Nail Lengths |

|---|---|---|

| Pin Nailer | 23 | 3/8″ – 2″ |

| Finish Nailer | 15-16 | 1″ – 2-1/2″ |

Another key difference is the type of nails each nailer can accommodate. Finish nailers can use a variety of nail types, including:

- Brad nails

- Straight finish nails

- Angled finish nails

Each type has its specific applications. For example, brad nails are more suitable for delicate trim work where splitting wood is a concern, while angled finish nails provide better access in tight corners. This flexibility makes finish nailers versatile in tackling more diverse woodworking projects.

I can’t overstate the importance of choosing the right nail size and type for your project. The success of your work hinges on this crucial detail, ensuring that everything stays in place without compromising the aesthetic appeal of the finished product. When you’re in the market for a nailer, weigh your options by considering the thickness of the materials you’ll be working with and the desired durability of the final construction.

Strength and Holding Power

When comparing pin nailers and finish nailers, strength and holding power are major factors to consider. It’s clear that the nail’s size has a direct impact on its holding power.

Pin nailers’ 23-gauge nails may be fine and almost invisible, but they lack the sheer holding strength of thicker nails. They’re ideal for delicate trim work where splitting the wood is a concern, but they shouldn’t be relied upon for structural strength. My experience has taught me that pin nails are best when used in conjunction with wood glue or when holding a piece temporarily in place until a stronger fastening method can be applied.

On the flip side, the 15 to 16-gauge nails used in finish nailers provide solid hold due to their larger diameter. They can securely fasten heavy trim, crown molding, and baseboards with ease. Coupled with their versatility in accepting different types of nails, this makes finish nailers the go-to choice for projects demanding durability.

Nail Length Matters

It’s not just the width that counts; the length of the nail is equally important when it comes to holding power. Finish nailers typically accommodate a wider range of nail lengths than pin nailers, which expands their capabilities even further. Here are some common lengths for each type of nailer:

| Type of Nailer | Nail Lengths (Inches) |

|---|---|

| Pin Nailer | 1/2 – 1 |

| Finish Nailer | 1 – 2 1/2 |

By leveraging longer nails, finish nailers can penetrate deeper into the work pieces, anchoring them more securely. I’ve found that for thick or layered materials, this added penetration depth can be the difference between a successful project and a failed one.

Nail composition can also contribute to the overall strength. Some nails have coatings that increase their grip within the wood, offering an additional layer of security. When maximum strength is needed, I’ll choose a nail with an adhesive coating that activates upon driving it into the wood, forming a bond that’s tough to beat.

Selecting the right nailer isn’t just about what looks best; it’s about knowing the demands of your project and understanding that sometimes, beauty and strength need to go hand in hand.

Applications and Projects

When I’m working on delicate trim pieces or crafting intricate woodwork, I consistently turn to my trusty pin nailer. It’s ideal for tasks where splitting wood is a concern, thanks to the small gauge nails it employs. With its near-invisible nail heads, it’s my go-to for:

- Attaching thin veneers

- Securing small trim pieces

- Crafting picture frames

- Assembling cabinetry components

The pin nailer’s discreet fastening capability makes it a perfect choice for detailed work where nails need to stay hidden. It’s not only about aesthetics; it also minimizes wood filler use, preserving the project’s integrity and finish.

Moving onto the finish nailer, the game changes when strength and versatility are top priorities. My finish nailer sees heavy-duty action on a diverse range of materials and thicker wood pieces where its larger nails can provide ample hold. The different types of nails available expand its utility across applications like:

- Installing baseboards and crown molding

- Building staircases

- Constructing cabinets

- Crafting hardwood floors

Moreover, when a project demands a balance between holding power and a clean finish, the finish nailer fits the bill. Its nails are big enough to secure, yet it’s still delicate enough to leave only a small footprint, easily concealed with a bit of wood putty.

The choice isn’t solely a matter of nail size or wood type; it’s equally about the end use of the item I’m building. For weight-bearing or structural elements, where the integrity is non-negotiable, finish nailers provide the necessary holding power. Meanwhile, for more decorative or non-supportive components, pin nailers offer a subtle approach, where finish is just as important as function.

As my projects vary, I lean on the unique benefits of each nailer. Assessing the task at hand allows me to determine whether the precision of a pin nailer or the robustness of a finish nailer will best serve the project’s needs. My tool choice can make a significant difference in the work process and end result, influencing everything from the construction speed to the maintenance of the wood’s pristine condition.

Conclusion

Selecting the right nailer is crucial for any woodworking project. I’ve found that understanding the subtle yet significant differences between pin and finish nailers can save time and improve the quality of your work. Whether you’re aiming for an almost invisible hold with a pin nailer or need the robust support of a finish nailer, choosing the correct tool is key to achieving those professional-looking results. Always consider the project’s specific demands and remember that the right nailer not only enhances construction speed but also preserves the integrity of your woodwork. With this knowledge, you’re now well-equipped to make an informed decision for your next project.

Frequently Asked Questions

What is the main difference between a pin nailer and a finish nailer?

A pin nailer is designed for delicate tasks and uses small gauge nails that are almost invisible to the eye. It’s perfect for trim work and intricate wood projects. A finish nailer, on the other hand, uses larger nails suitable for projects requiring more hold and is better for installing baseboards, crown molding, and other structural work.

When should I use a pin nailer?

You should use a pin nailer when working with thin veneers, small trim pieces, crafting picture frames, or assembling cabinetry components where the nails should not be visible. It’s ideal for delicate or precision work.

When would a finish nailer be the better choice?

A finish nailer is the better choice for projects that demand strength and durability. This includes installing baseboards, crown molding, building staircases, constructing cabinets, and laying hardwood floors. It’s suitable for structural and weight-bearing applications.

Can pin nailers be used for structural projects?

No, pin nailers are not recommended for structural projects as they use smaller nails that don’t provide significant holding power. They are meant for decorative or non-supportive work.

If I can only purchase one, which nailer should I choose?

The nailer you should choose entirely depends on the types of projects you plan to undertake. If you’re focused on precision work and aesthetics, choose a pin nailer. If you’re looking at construction or structural work that requires strength, a finish nailer will be more appropriate. Assess your specific project needs carefully before making a decision.

Reader Interactions