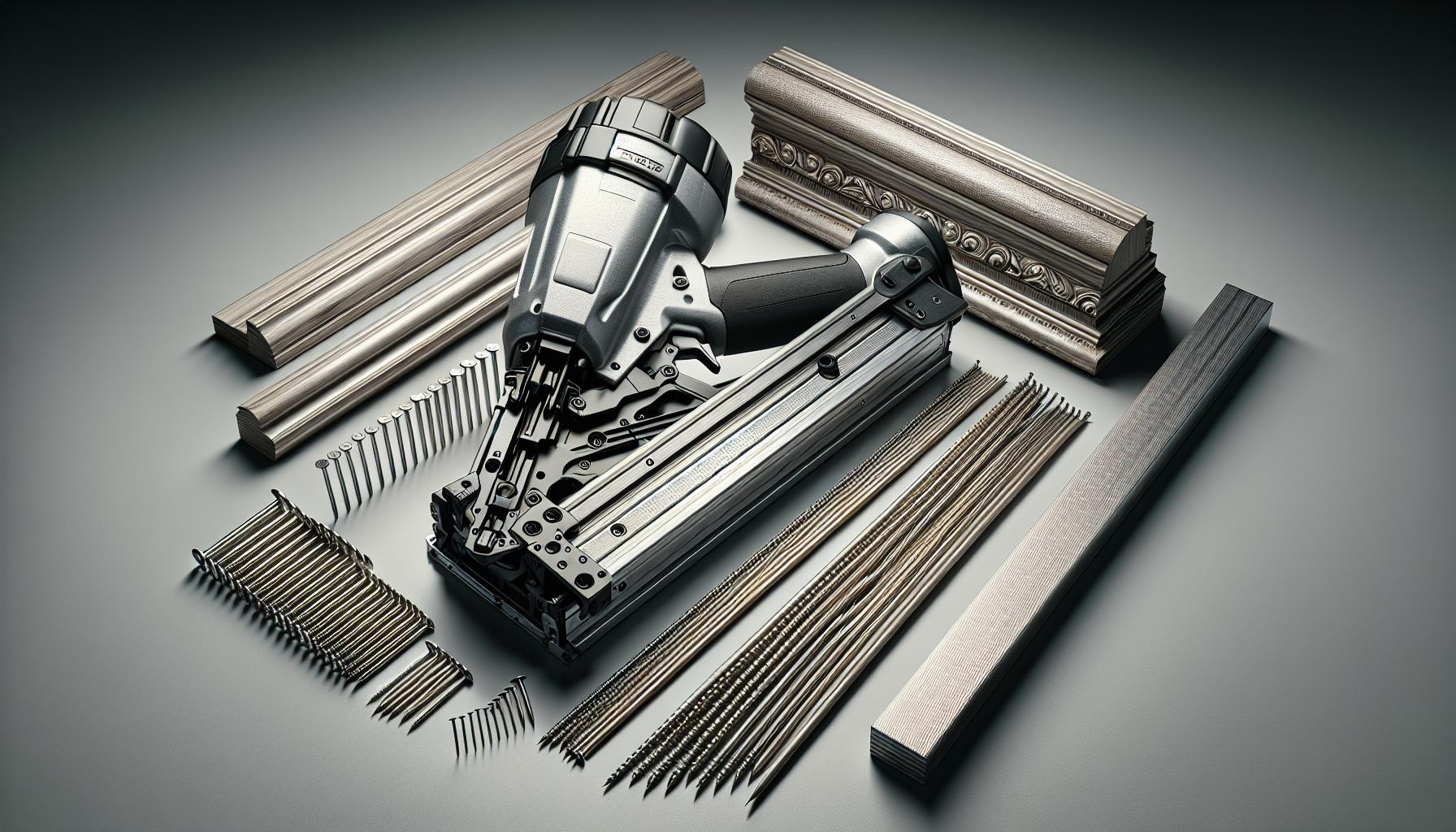

When tackling a woodworking project, choosing the right tool can make all the difference. I’ve been there, standing in the tool aisle, trying to decide between a 16 gauge finish nailer and an 18 gauge brad nailer. It’s a common dilemma for DIY enthusiasts and professionals alike.

The 16 gauge finish nailer is known for its robust nailing capabilities, perfect for those heavier trim and molding tasks. On the other hand, the 18 gauge brad nailer is a go-to for finer, more delicate work. It’s all about precision without splitting the wood.

In this article, I’ll dive into the nuances that set these two nailers apart. I’ll help you understand when to use each one, ensuring your next project is nailed to perfection.

Understanding the Differences

In navigating the nuanced world of nailers, it’s crucial to understand that 16 gauge finish nailers and 18 gauge brad nailers serve distinct purposes. These tools may appear similar at first glance, but their subtle differences have significant implications for their best use cases.

A 16 gauge finish nailer offers greater holding power due to the thicker nails it uses. These nails, often ranging from 1 to 2.5 inches in length, are ideal for attaching heavier trim pieces that require a more secure fastening. In my experience, this sturdiness becomes especially important in projects involving door jambs, stair treads, or robust crown molding.

On the other hand, an 18 gauge brad nailer uses thinner nails, typically ranging from 5/8 to 2 inches. Because of its smaller diameter, brad nails reduce the likelihood of splitting delicate trim or causing unsightly blemishes. I’ve found brad nailers to be the perfect companion when working on intricate woodwork or trim that needs a subtle touch.

Here’s a simple comparison to keep in mind:

| Feature | 16 Gauge Finish Nailer | 18 Gauge Brad Nailer |

|---|---|---|

| Nail Thickness | Thicker (16 gauge) | Thinner (18 gauge) |

| Best for | Heavy trim and molding | Delicate trim work |

| Nail Lengths Available | 1 to 2.5 inches | 5/8 to 2 inches |

| Holding Power | Higher | Less |

Contemplating the specifics, I must emphasize build quality as well. Higher-quality nailers, irrespective of gauge, tend to lead to smoother operation and less maintenance down the line. It’s not just about size; it’s how robustly the tool can handle consistent use.

When assessing a project, consider factors such as the material you’re nailing into, the visual finish you desire, and the structural demands of your build. With a clear purpose in mind, choosing between a 16 gauge finish nailer and an 18 gauge brad nailer becomes a straightforward decision.

Nailing Capabilities of a 16 Gauge Finish Nailer

When I’m tackling larger trim and molding projects, I often turn to my trusty 16 gauge finish nailer for its robust nailing capabilities. The thicker nails, typically measuring 1.6mm in diameter, offer increased holding power essential for heavier materials. This means when I’m installing baseboards, door casings, or window trim, I can rely on this nailer to secure the pieces with a strong bond that’s less likely to loosen over time.

A 16 gauge finish nailer can handle various lengths of nails, usually ranging from 3/4 inch to 2-1/2 inches. The flexibility in nail size allows me to adjust based on the thickness of the trim wood I’m fastening. For example, I’d choose a longer nail to ensure it adequately penetrates through a thick piece of crown molding and into the wall stud or ceiling joist for a secure fit.

Here’s a quick rundown of the nailing range you’d expect from a 16 gauge finish nailer:

| Nail Length (inches) | Common Uses |

|---|---|

| 3/4 to 1 | Light trim work, small moldings |

| 1-1/4 to 2 | Standard baseboards, chair rails |

| 2-1/4 to 2-1/2 | Larger crown molding, door casings |

Unlike its 18 gauge counterpart, the 16 gauge nailer packs enough punch to fasten thicker, denser woods without bending or wobbling. This makes it a preferable choice for hardwood applications where a smaller gauge might fail. Moreover, the head of the 16 gauge nail is larger, which although more visible, provides a greater surface area for the nail to grip onto the material.

It’s also worth mentioning that while the 16 gauge nails do leave a more prominent hole, this typically isn’t an issue since in most cases, trim is painted post-installation and nail holes are filled and sanded down. The result is a clean, smooth finish that masks any sign of nailing.

Nailing Capabilities of an 18 Gauge Brad Nailer

When considering the 18 gauge brad nailer, it’s important to note that it’s designed for precision work. Unlike the 16 gauge finish nailer, which is ideal for heavier trim, an 18 gauge nailer is fantastic for attaching lighter trim and molding where wood splitting is a concern. It’s the go-to choice for delicate trim pieces, such as shoe moldings and quarter-rounds. Here’s why this tool is so essential for finer woodworking projects:

Firstly, 18 gauge brad nails are thinner, meaning they’re less likely to split the trim or the wood they’re being nailed into. This feature establishes the brad nailer as a safer option for thin veneers and small, thin strips of trim. Their finer size results in a smaller hole, which is barely noticeable and often doesn’t require wood filler if the wood is to be left natural or stained rather than painted.

The versatility of the 18 gauge brad nailer becomes apparent with its ability to handle nails usually ranging from 5/8-inch to 2 inches in length. Therefore, my use of this tool often extends beyond trim work; I’ll utilize it for:

- Light wood assembly

- Paneling

- Picture framing

- Making cabinetry

Another significant advantage is the lack of marking on the wood. Since the 18 gauge nailer operates with less force than a 16 gauge nailer, it’s less likely to leave a dent or mark around the nail entry — a quality especially desired in fine finishes or softer woods.

When I’m faced with projects demanding utmost precision, the 18 gauge brad nailer is my reliable partner. It’s capable of providing a strong enough hold for lightweight trims and moldings without the bulkiness or excessive power that could potentially damage the wood. With this nailer, the focus is on a clean finish and maintaining the integrity of the wood, down to the finest detail.

Factors to Consider when Choosing

When you’re in the market for a nailer, weighing the differences between a 16 gauge finish nailer and an 18 gauge brad nailer is crucial. Several factors should guide your decision:

Project Material

Your choice should align with the types of materials you frequently work with. If you’re handling softer wood or delicate trim, the 18 gauge brad nailer’s thinner nails are less likely to cause splitting. For heavier trim or thicker materials, the 16 gauge finish nailer’s thicker nails offer more holding power.

Nail Size

The size of the nails is another critical factor. Here’s a quick breakdown:

- 16 Gauge Finish Nailer: Generally accepts nails from 1 inch to 2-1/2 inches.

- 18 Gauge Brad Nailer: Nails range from 5/8-inch to 2 inches in length.

Longer nails provide a stronger hold, so choose according to your project’s stability requirements.

Desired Finish

If you’re after a clean, nearly invisible finish, the smaller holes left by an 18 gauge brad nailer may be preferable. However, if the holes will be covered or filled and the finish isn’t a top concern, a 16 gauge finish nailer could suffice.

Tool Use Frequency

Consider how often you’ll use the tool. For occasional use, you might prefer the versatility of an 18 gauge brad nailer. If you’re a professional who uses the tool regularly for a range of applications, investing in both types ensures you’re equipped for any job.

Remember, the right nailer can enhance your efficiency and the quality of your work. By considering the material, nail size, desired finish, and use frequency, you’ll hone in on the perfect nailer for your toolbox. Whether it’s an 18 gauge brad nailer for precision work or a 16 gauge finish nailer for sturdy applications, there’s a tool for every project.

Applications for a 16 Gauge Finish Nailer

When tackling a variety of carpentry and woodworking tasks, it’s essential to have the right tool. The 16 gauge finish nailer is a versatile instrument in my arsenal, designed for projects that require a bit more holding power than what an 18 gauge brad nailer offers. I’ve found that its applications are quite extensive, making it a must-have for serious DIYers and professional carpenters alike.

Interior Trim Work: The 16 gauge nails are the perfect size for the installation of door casings, crown moldings, and baseboards. They provide a secure hold, ensuring the trim stays in place. Due to their size, they can handle the slightly heavier trim work without splitting the wood, which I find particularly useful when working with delicate materials.

Cabinet Building and Installations: Building cabinets demands precision and reliable hold. The nails used in a 16 gauge finish nailer are solid enough to assemble parts of the cabinets and hold them together, even under the strain of heavy use. I prefer using this nailer when installing cabinets as well because it anchors them firmly to the wall.

Exterior Trims and Projects: For projects exposed to the elements, a 16 gauge finish nailer provides the added durability needed. It’s great for exterior trim, including fascia and soffit installations. The nails can stand up to the outdoor conditions better than the smaller 18 gauge nails.

Staircases and Railings: When securing handrails and balusters, the beefier 16 gauge nails offer the strength required to support the weight and resist the force exerted on them every day. I trust this nailer to keep stair components tightly fastened and secure.

While there are many nailers on the market, knowing where to best apply the use of a 16 gauge finish nailer can make a significant difference in the efficiency and outcome of a project. Identifying the appropriate application ensures not only the completion of the work but also the lasting quality and durability of the finished product.

Applications for an 18 Gauge Brad Nailer

When it comes to delicate woodwork or thinner trim, an 18 gauge brad nailer is typically my go-to tool. Given its thinner nails, it’s an ideal choice for projects where a smaller nail hole is preferable, ensuring a neater finish that often doesn’t even require wood filler.

Here are several key applications where an 18 gauge brad nailer shines:

- Attaching lightweight trim like shoe moldings and quarter-rounds. Its finesse helps in reducing the risk of splitting the wood.

- Securing paneling and beadboard, as the smaller nails provide sufficient hold with less visibility.

- Constructing picture frames or assembling cabinetry where the size of the nail must be minimized.

- Craft and woodworking projects that involve thinner stock or intricate details.

Using an 18 gauge brad nailer for these projects does more than just preserve the integrity of the material. It streamlines the finishing process because there’s less puttying and sanding needed after the nails are in place. This can be a major time-saver for hobbyists and professionals alike.

Additionally, brad nailers are often lighter in weight and more maneuverable compared to their 16 gauge counterparts. If you’re working on a project that requires a lot of holding or reaching, like installing crown molding, that reduced weight can reduce arm fatigue and help to maintain precision during long stretches of work.

When detailed craftsmanship is paramount and the finish needs to be as clean as possible, opting for an 18 gauge brad nailer is generally the smarter choice. Its ability to discreetly and efficiently handle fine carpentry work can’t be overstated and can greatly affect the outcome of your project.

Pros and Cons of Each Nailer

When deciding between a 16 gauge finish nailer and an 18 gauge brad nailer, it’s important to weigh their advantages and drawbacks based on my extensive experience working with both.

16 Gauge Finish Nailer Pros

- Provides a stronger hold due to thicker nails, which is essential for heavy trim and baseboards.

- Versatile enough for indoor and outdoor projects, such as door and window casings or exterior trim.

- Ideal for projects that require more structural support.

16 Gauge Finish Nailer Cons

- Leaves larger holes that may need to be filled and sanded for a smooth finish.

- Less maneuverable than its 18 gauge counterpart, potentially leading to user fatigue during extended use.

18 Gauge Brad Nailer Pros

- Perfect for delicate trim and finish work where a minimal nail footprint is desired.

- Lightweight and easy to handle, reducing arm fatigue and increasing precision for detailed projects.

- Generally offers a better solution for intricate woodworking tasks due to its smaller nail size.

- Not as suitable for heavy duty applications as the 16 gauge nailer, with less holding power.

- May not provide adequate support for larger, heavier trim pieces or other substantial carpentry work.

By understanding the strengths and limitations of each nailer, I can choose the right tool for the job that will deliver superior results. The 16 gauge finish nailer is my go-to when I need durability and holding power. On the other hand, I lean towards the 18 gauge brad nailer for jobs where the finish is paramount and the materials are more delicate. Each nailer has its ideal use-case scenarios where it outperforms the other, which makes them both valuable tools in my arsenal. Whether I’m undertaking a simple craft project or tackling extensive installation work, knowing these pros and cons ensures that the nailer I select will meet the specific demands of the job at hand.

Conclusion

Deciding between a 16 gauge finish nailer and an 18 gauge brad nailer boils down to your specific project needs. I’ve highlighted the robust hold of the 16 gauge and its suitability for a range of tasks, alongside the precision and finesse that the 18 gauge offers for more delicate work. Remember, it’s not about which nailer is superior but which one aligns with your work requirements. Choose wisely, and your nailer will become an indispensable ally in your tool arsenal.

Frequently Asked Questions

What is the main advantage of a 16 gauge finish nailer?

A 16 gauge finish nailer offers a stronger hold, making it suitable for both indoor and outdoor projects that require more durable fastening.

When should I use an 18 gauge brad nailer?

You should use an 18 gauge brad nailer for delicate trim and finish work. It is the preferred choice for projects where a less visible nail hole is desirable.

Does a 16 gauge finish nailer leave large holes?

Yes, due to its thicker nails, a 16 gauge finish nailer leaves larger holes compared to an 18 gauge brad nailer.

Is an 18 gauge brad nailer suitable for heavy-duty projects?

No, an 18 gauge brad nailer may not have the necessary holding power for heavy-duty applications as it is designed for lighter trim and finishing tasks.

Which nailer is more maneuverable?

An 18 gauge brad nailer is generally more maneuverable due to its lighter weight and smaller size, making it easier to handle for precise work.

Can both nailers be used for indoor and outdoor projects?

While both nailers can be used indoors, the 16 gauge finish nailer is more versatile and can be used for outdoor projects due to its stronger hold. The 18 gauge brad nailer is better suited for indoor work.

Reader Interactions