A circular saw is one of the most popular hand-held power saws in the world. Used both by professionals and hobbyists there is a reason why you’ll find them in nearly every workshop and job site. Not much else can compete with the power, effectiveness and usability of a circular saw.

Due to how good they are, many versions are now available, two of them being the worm drive and sidewinder variants. At first glance, they may seem the same but we know this not to be the case. The following article is designed to help you understand each difference and if you’re in the market for one, make the decision process a whole lot easier!

What’s The Difference?

| Worm Drive | Sidewinder | |

| Motor type | Worm drive | Spur gear |

| Motor position | Behind blade | Side of blade |

| Handle position | Rear | On top |

| Blade position | Left * | Right * |

| RPMs | 4500 * | 5500 * |

| Torque | High | Lower |

| Weight | 16 lbs * | 10 lbs * |

| Maintenance | Motor oil | None |

| Prices from | $150 + | $50 + |

* Indicates typical values but will vary with different models

Visual & Usability Differences

It doesn’t take long to notice clear visual differences between these two saws. So, before we get into the performance side of things, let’s explore how they differ visually and how this may affect their usability. First of all, worm drive saws have a much longer and narrower profile compare to the short and wide appearance of a sidewinder. The reasoning behind this is due to the positioning of their motors.

The motor in a sidewinder saw is positioned next to the blade. This results in a short yet wider profile we mentioned above. Because the motor is more centrally located, sidewinder saws are lighter and easier to maneuver than a worm drive saw. This makes them more accessible to first time and less experienced users.

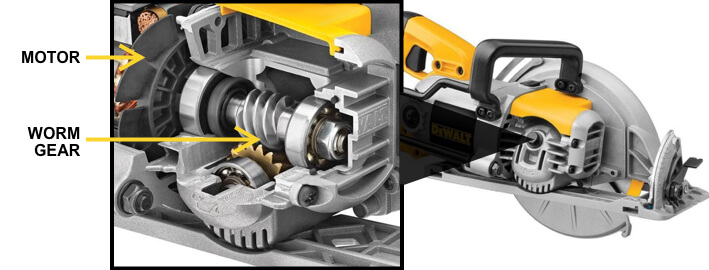

With worm drive saws, the motor is positioned directly behind the blade which gives it a longer and narrower profile. The final and perhaps most obvious visual difference between the two saws is the positioning of the blade.

Blade Positioning

Worm drive circular saws are known for their ‘left side’ blade positioning, whereas sidewinders are known to have their blade positioned to the right. But what significance does this have for the user?

Quite a lot!

Cutting line visibility is an important factor when using any saw. A blade on the right-hand side for a right-hand user will be detrimental to their line of sight and make it harder for them to get a clear view of what they are cutting. This means left-handers should go with a sidewinder saw for its right-side blade, and right-handers should go with worm drive saws for their left side blade.

Motor Torque

Torque refers to the rotating force of the saw blade. Saws with greater torque can perform more work and handle tougher materials. So, which of these saws produces the higher torque? The answer, a worm drive saw. The way worm gears work enables it to produce greater torque due to the larger teeth of its gears which enables more load-carrying capacity, however, this means lower RPMs.

Regular circular saws use what’s technically called a spur gear. Due to the way these work, the motor must be in line with the blade. This formation allows the blade to spin faster.

Blade Speed

Blade speeds aren’t the same between each saw due to the positioning of the blade in relation to the motor and the subsequent turning mechanism. Despite worm drive saws producing greater torque, it is a sidewinder saw that produces the faster blade speeds (around 5,500 rpm). This is because the motor sits directly in line with the blade which results in the use of a spur-gear.

On the other hand, the motor in a worm drive saw is positioned behind the blade. To transfer power to the blade a gear system is used. This gear system lowers blade speeds down to around 4,500 RPM.

Weight

Sidewinder saws are lighter and have more favorable weight distribution due to their centrally-located motor. This makes them more suited to overhead work.

Worm drives are heavier due to the worm geared motor. However, this weight can come in handy when if using it to your advantage making cuts by hand.

Corded vs Cordless

The corded vs cordless debate is a tough one which ultimately comes down to your unique requirements.

Sidewinders are now pretty common in cordless versions and the latest models have enough power to rival corded models. These come at an additional cost if you can afford them. If you are on a budget, it’s best to stick to the trusted corded models.

While there are “worm style” cordless circular saws on the market, they are not true worm drives as they are not using a worm gear motor – they are powered using batteries and a direct drive system. Despite this, they still have the rear handle, left side blade and torque required for contractors to use.

Making your Decision

Deciding between a worm drive or sidewinder circular saw certainly isn’t an easy task. You need to decide on your top priorities and go with the saw that best fits them. Need maximum power? Then go with a worm drive saw. Lack of previous saw experience and feel slightly apprehensive about using one? Try a sidewinder.

With blade orientations starting to become less defined to one model, both types are now viable options to both right and left-handed users. No matter which you chose, both have their merits and should not disappoint.

Recap

- If power is your no.1 priority, go with a worm drive circular saw.

- Sidewinder for cutting softwood and cross-cutting.

- Worm drive for hardwood and long rip cuts.

- Worm drive saws tend to be the heavier of the two.

- A Sidewinder saw is more suited to less experienced users.

- Lower budget? Then go with the more affordable sidewinder saw.

Reader Interactions