If a job is worth doing, it is worth doing right!

To do a job right you need to use the correct tools, but sometimes it is easier said than done. This is especially true when it comes to power saws. With so many available it seems like there is one for every job under the sun.

Don’t worry, we have put in the research so you don’t have to and compiled it into the following article. We will explore the benefits of a track saw vs a circular saw, whether a track saw can be used as a circular saw and how they differ in regards to price.

Upon finishing you should have a solid understanding on which saw will suit you best. Let’s get started!

Benefits of a Track Saw vs a Circular Saw

When comparing any tool with another there will always be some things that one does better than the other, and vice versa. This is no different when it comes to comparing a track saw vs a circular saw. Here are some of the main benefits:

1. Plunge cutting

Unlike a circular saw, a track saw is designed with the blade inside the machine itself. As a result, they do not need a standard retractable blade guard. This allows them to perform easy plunge cuts and is why you will occasionally see them referred to as a plunge saw.

Although circular saws are designed to make cuts from the edge of materials, the retractable blade guard doesn’t completely stop them from making plunge cuts. The process involves holding the front edge of your circular saw down firmly to the material. Next, lift the up blade guard and line up the blade with your cutting line. Finally, start up the saw until it reaches full speed and slowly lower it into the material.

This can be quite awkward and will require some skill, it is also rather dangerous. If you do try it, remember to always saw away from you and watch out for the inevitable kickback! At the end of the day, if you need to make plunge cuts, go with a track saw!

2. Effective dust extraction

Another added benefit a track saw experiences with its enclose blade is improved dust extraction. It effectively traps dust and with an added vacuum you’ve virtually got no mess.

Dust extraction helps in various ways from clearing your line of slight allowing for a faster cut, less cleanup and can prevent the user from inhaling dangerous particles. Dust extraction on a circular saw can be hit and miss as not all models feature a dust extraction system.

3. Sawing accuracy every single time

When it comes to cutting accuracy, the track saw comes out as the clear winner. The ability to use it alongside a guide rail guarantees a precise cut every single cut. All you need to do is align it with the markings made on your cutting material and you’re ready to start cutting. The guide rail will show exactly where your cut will be made, leaving the guesswork completely out of it!

Also, the rails feature non-slip material strips underneath to prevent movement during a cut and can be clamped using rail clamps if you need the extra stability.

You can even maintain that accuracy on long cuts. Additional guide rail lengths can be purchased depending on your cutting needs and with some connectors, they allow you to make extra long straight line cuts – even up to 100ft!

Compare that to using a circular saw – you cannot guarantee consistent and exact cutting accuracy from a side fence.

4. Super smooth & clean cuts

It’s all well and good being able to make quick and easy cuts but if they leave behind a poor finish the time you thought you saved will have to be spent sanding to clean them up.

Fortunately, track saws produce some of the cleanest cuts out of any power saw going. Part of the reason for this is the splinter guard built into track saws. They are designed to improve results when cutting material that has a high likelihood of splintering.

Your circular saw is only designed to make quick cuts so you’ll find the finish is very rough and splintered compared to a track saw.

6. User Safety & Experience

The enclosed blade design of a track saw which limits blade exposure combined with the riving knife makes them much safer for new and less experienced users over a circular saw. The method of cutting along a guide rail also means little to no previous power saw experience is required to operate one.

Can you use a Track Saw as a Circular Saw?

Having seen what a track saw is capable of, you may be wondering if you can use one as a circular saw. To answer this we must explore the benefits of a circular saw and see how the track saw compares.

A track saw requires 2 hands

When it comes to using a circular saw, the usual method is to use one hand. This leaves a hand free which can be used to brace the material you are cutting.

Track saws, however, require both hands as you first need to plunge the saw blade in your cutting material then move it forward to perform the cut. Attempting this one-handed is exceptionally tricky.

Circular saws are better for quick cuts

Circular saws are known for their ability to make quick and accurate cuts into a variety of materials. For example; if you need to make a few quick cuts you’re better off reaching for a circular saw as it doesn’t require any setup.

Conversely, to experience the full potential of a track saw you must use it alongside a guide rail which does require setting up, adding time to your project.

Circular saw blades also tend to be less expensive which is another reason to use it for odd cuts.

Circular saws are great in construction jobs

Circular saws typically feature a larger and more powerful 15 amp motor compared to the usual 10 or 12 amp motors found in a track saw. This makes them much more suited to heavy construction style work like framing lumber with a worm drive saw.

Also, because the most common blade diameter for circular saws is 7.25’’ compared to 6.5’’ for track saws, circular saws likely have an extra 5/8’’ depth of cut.

Circular saws work better in tight spaces

On occasion, you might find yourself needing to perform cuts in tight spaces. This is relatively straight forward for a circular saw but impossible for a track saw on guide rails. Not only are circular saws more convenient for quick cuts they are more portable and easier to store away while not in use. Although track saws aren’t the biggest of saws, they will take up more room than a circular saw. Assuming you have a guide rail, which you should, you’ll need somewhere to store that as well.

So, can you truly use a track saw as a circular saw? On paper yes you probably could but in reality, I wouldn’t recommend it.

How you answer this depends on what you’re using it for. Have a construction project coming up and need power saw, a track probably won’t cut it. If, however, you have a smaller scale DIY job that needs doing then a track saw should have you covered.

At the end of the day, they are two different tools with different features. Also, there is no need to use a track saw as a circular saw when you can pick up a circular saw for as little as $40.

Why does the Track Saw Cost so much more?

If you’ve already had a look at various track and circular saws you may have noticed track saws cost more, especially when compared to the cheapest circular saws. But why is this the case?

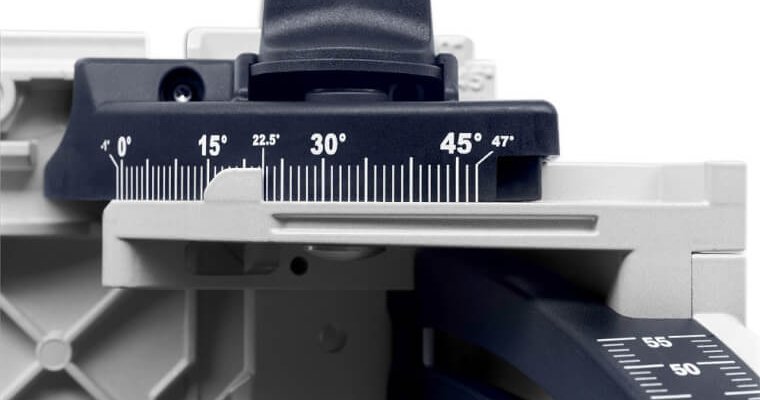

One of the key factors is to do with the track saw’s accuracy and the impressive amount of adjustable settings – so the user can dictate their cut with an incredible level of accuracy. If you were to purchase a track saw, you’d have a depth stop, depth gauge and front and rear bevel capability with locking features.

Other added value which you do not get with a regular circular saw is

- Splinter guards which help reduce chipping and leaves behind a better finish.

- Most track saws also cut virtually dust free when hooked up to a vacuum thanks for the inclosed blade design.

- Some packages include the track / guide rails.

With the cutting ability and quality of a table or mitre saw it a compact and portable package it is clear to see why manufacturers feel justified charging a higher price for them over a generalist circular saw.

What’s the Best Saw to Buy?

It is important to remember these saws are not the same, as much as it might seem like it. So, which saw is the best one to buy? Your decision comes down to a few important factors.

One of the most important being the quality of cut. A track saw is the clear winner here. Once set up on a guide rail a track saw will produce much better quality cuts that are dead accurate, easily repeatable and aren’t left with splintered edges due to the in-house plastic splinter guard.

Read our track saw reviews here

If you’d prefer a more powerful and flexible sawing experience with a much more hands-on approach, go for a circular saw. You’ll also save a fair amount of money on the saw itself and the extra blades.

Read our circular saw reviews here.

If you find yourself wanting both, go for a quality track saw that will last for a long time and a budget circular saw that won’t set you back a lot but still do the jobs you expect from it.

Reader Interactions